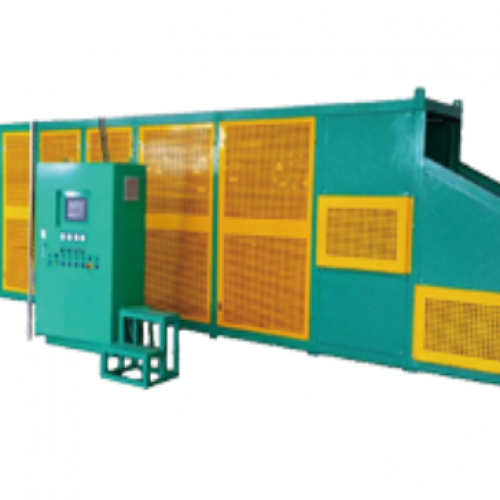

Mesh Type Batch Off Machine

Categories : Rubber Cooling Machines

The main function of batch off machine is for cooling and storage of rubber sheet. Then, the rubber sheet after cooling will be delivered to next process. THE MAIN STRUCTURE OF MESH TYPE BATCH OFF MACHINE CONSISTS OF SHEET INLETSECTION, SHEET STORAGE SECTION AND SHEET OUTPUT SECTION.

Batch-Off Machine

Categories : Dosing and Measuring Equipment

Sheeting For Rubber Industries We will following customer inquiry to add stripping device、collecting device or metal detector, or other special device.

HANGER TYPE BATCH OFF MACHINE

Categories : Rubber Cooling Machines

The main function of batch off machine is for cooling and storage of rubber sheet. Then, the rubber sheet after cooling will be delivered to next process. The cooling method of batch off machine can be fan cooling, water cooling and air cooling for matching to different requirement. We have hanger type and flat type (mesh type) batch off machine according to different delivery method of rubber sheet.

Auto Batch Vacuum Foaming System SA-1BVF

Categories : Vacuum Forming Machines

The SA-1BVF can be used with an existing auto batch foaming machine or with SUNKIST's own SA-1B, SA-1BS, SA-1BM and SA-1HA. After the mixture is loaded into mold box, the mold box is moved into this chamber via a carriage. After the mold box us placed inside the curing chamber, the door of the chamber automatically closes and shut tightly. An operator can then adjust the pressure inside the chamber with the control panel. The quality and physical properties of the foam that is formed will be affected when the pressure is changed, ie. the volume of the foam size will increase, foam tensile strength will also increase dramatically, and the hardness of the foam will change. This machine is environmental friendly, reduce the amount of chemicals used and reduce the fire risk.

Auto Batch Mixing Machine

Categories : Vacuum Forming Machines

Suitable for small to medium scaled foam factory. Block foaming machine consists of mixing system with moving forward and backward device. Metering system with re-circulation flow to control chemicals which are dosed from the chemical storage tanks through pipe work and pneumatic injection valve systems into the mixing barrel. As soon as the mixing time elapses, the hatch of mixing barrel will automatically open to load the mixture smoothly into the mold and close the hatch then can draw it backward to its original position automatically. No need to clean the mixing barrel between each shot.

Batch Off Machine (Hanger Type & Net Type & Hanger Carriage Type)

Categories : Rubber Cooling Machines

This Machine For Rolls To Sheet Cooling Equipment, We Have 「Hanger Type」「Net Type」「Hanger Carriage Type」 Three Kind, The Cooling Type Have 「Water Cooling」「Fan Cooling」「Air Cooling」 Three Style, The Machine Have Three Area 「Sheet Inlet Section」「Sheet Storage Section」「Sheet Output Section」 The Sheet First Into Inlet Section Powder Water Tank To Soak, Then Into Sheet Storage Section To Hang Or Place Dry And Cooling, Then Into Sheet Output Section Automatic Cut Strip Or Pile Up To Collect, And Continuity Produce Supply Equipment The Best Automation Produce Effect.